How Direct Fired Heaters Are Used in Different Industries

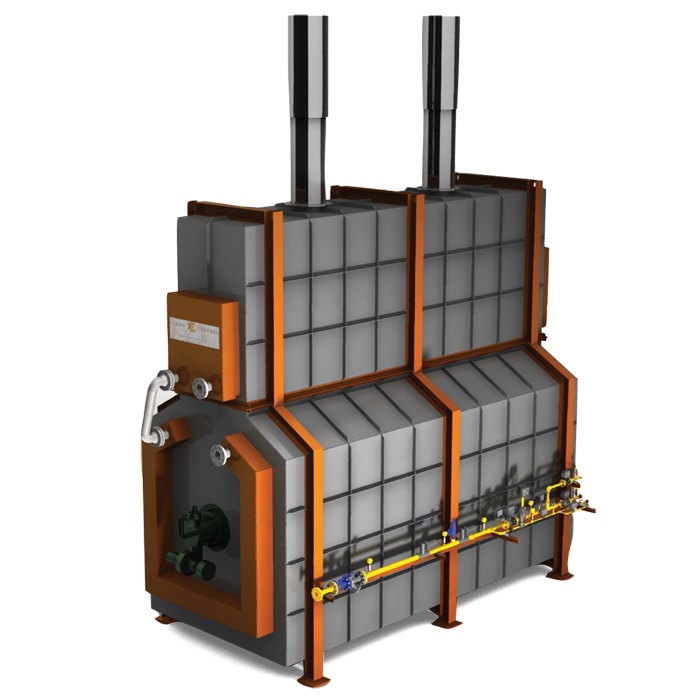

Direct fired heaters create heat by burning oil, natural gas, or other fuels. The heaters have an insulated enclosure that uses the heat from fuel combustion to heat fluid-filled coils. Fired heaters are essential in many applications, including chemical plants and refineries, for efficient industrial process operations that rely on elevated temperatures. Direct fired heaters also come in several types based on your specific needs. Here, we will explore the most common applications of industrial direct fired heaters.

Oil, Gas, and Petrochemical Industries

The oil, gas, and petrochemical industries depend on industrial direct fired heaters for daily operations, such as:

- Heating Hot Oil: Direct fired systems can heat oil and maintain it within precise temperature ranges for heat transfer efficiency in systems like reactors and heat exchangers. As a result, direct fired heaters improve overall process efficiencies and reduce energy consumption.

- Crude Oil Heating for Separation: Direct fired heaters are essential in crude oil refining processes. They heat crude oil to precise temperatures during processes such as distillation, which separates various crude oil components based on their respective boiling points. Thus, fired heaters are critical in improving the efficiency of refining petrochemicals, diesel, and gasoline.

- Cracking Processes: In cracking processes, direct fired heaters elevate the temperature of hydrocarbons, breaking them down to produce products like ethylene. The cracking process is essential to producing ethylene for the many industrial applications that rely on this compound.

- Other Uses: Direct fired heaters are also essential in heating gas pipes, regeneration gas, industrial gas, and high-pressure hydrocarbon gas at pressure-reducing stations. Other applications include the vaporization of gases and liquids, aromatic furnaces, steam superheaters, and dew point control systems for combustible gas in turbine plants.

Aerospace Industry

Direct fired heaters used by Sigma Thermal, particularly in the aerospace industry, are primarily designed for high-temperature air heating applications. These heaters are vital in simulating turbine flue gas conditions to test various aerospace components and designs. The heated air, often reaching temperatures as high as 1500°F (800°C), replicates the harsh environments that turbines and aerospace materials endure. This enables manufacturers to validate the performance and durability of parts under controlled, real-world conditions before actual deployment. This application is essential for ensuring the safety and efficiency of aerospace designs.

Food and Beverage Industry

In the food and beverage industry, most frying and cooking processes currently use indirect fired heaters to heat the cooking oil. However, some food processing applications are starting to use direct fired heaters to circulate the frying oil through the boiler, similar to elution heaters. These systems tend to be complex because they must consider the fast oxidation of oil in these applications.

Learn More With Sigma Thermal

Industrial direct fired heaters are used to elevate and maintain temperatures in various applications, such as oil, gas, petrochemical, mining, and food and beverage processing. Often, these heaters are custom-made for their intended application, such as elution heaters for mining.

Sigma Thermal offers various industrial direct fired heaters, heat exchangers, and other heating solutions for every application. When you work with Sigma Thermal, you get tailored solutions from our experienced industry professionals and dedicated staff. Our engineers and technicians have the expertise to deliver solutions for your specific project, whether you are looking for a standard packaged heater, servicing of an existing heater, a tune-up to optimize your current system, or an advanced process heating system.

Contact us or request a quote to connect with a specialist about your process heating needs.