Direct Fired Heaters

Sigma Thermal offers convection style, API 560, and non-API radiant convective heaters from 1MM to 80MM Btu/hr.

A direct fired heater is a style of heater in which a burner provides hot gasses that transfer their heat energy to a process liquid or gas flowing directly through coils installed inside the heater vessel. Direct fired heaters can utilize radiant and/or convection heat transfer sections, and can be configured in many different ways depending on the customers’ specific requirements. Due to the flexibility in design, virtually any style of furnace burner can be used in single or multi-burner configurations. For help selecting the right solution for your project, contact our application engineers today.

A direct fired heater is a style of heater in which a burner provides hot gasses that transfer their heat energy to a process liquid or gas flowing directly through coils installed inside the heater vessel. Direct fired heaters can utilize radiant and/or convection heat transfer sections, and can be configured in many different ways depending on the customers’ specific requirements. Due to the flexibility in design, virtually any style of furnace burner can be used in single or multi-burner configurations. For help selecting the right solution for your project, contact our application engineers today.

Convection Heater

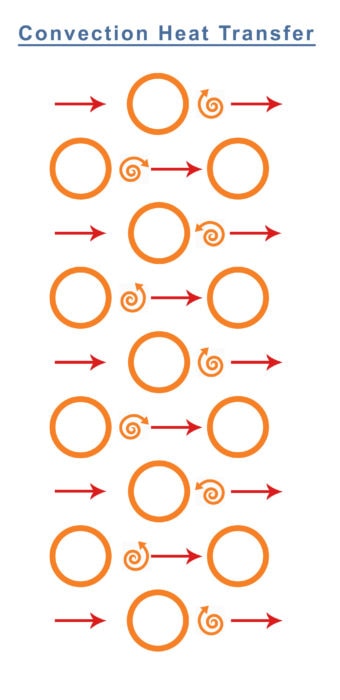

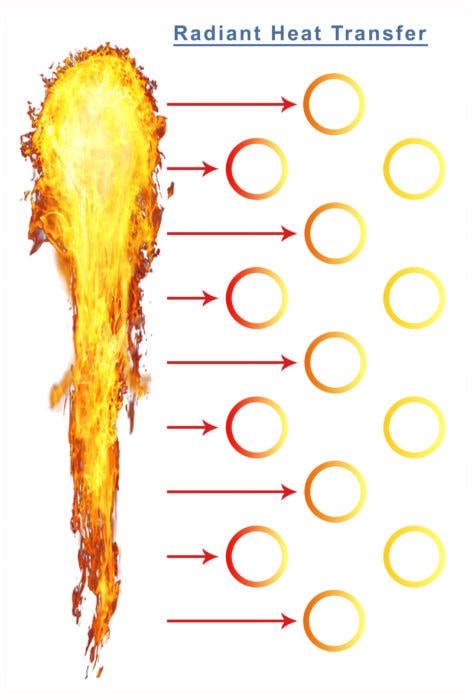

A convection style heater offers the benefits of a direct fired heater while eliminating some of the drawbacks associated with radiant heat transfer. Radiant heat transfer can be undesirable in certain temperature-sensitive applications as radiant heat transfer tends to be more intense and unevenly distributed around the coil surface. Sigma Thermal’s convection style direct fired heater utilizes a separate combustion chamber and flue gas recirculation to reduce combustion chamber temperatures to 1,400F, thereby minimizing the impact of radiant heat transfer to the process coil.

A convection style heater offers the benefits of a direct fired heater while eliminating some of the drawbacks associated with radiant heat transfer. Radiant heat transfer can be undesirable in certain temperature-sensitive applications as radiant heat transfer tends to be more intense and unevenly distributed around the coil surface. Sigma Thermal’s convection style direct fired heater utilizes a separate combustion chamber and flue gas recirculation to reduce combustion chamber temperatures to 1,400F, thereby minimizing the impact of radiant heat transfer to the process coil.

Design Features

| Row by Row Sizing Method | This detailed sizing method allows for accurate prediction and precise control of heat flux and film temperatures on each individual tube row. |

| Coil Configuration Flexibility | Coil flow path and metallurgy are engineered for each customer’s process requirements. Sigma Thermal has extensive experience in process coil design for multi-phase fluids, viscous hydrocarbons, suspended solids, and various gaseous mixtures. |

| Fuel Source and Burner Flexibility | Standard or engineered burner configurations are available for use with both traditional and alternative fuel sources. Low emissions burners can be supplied to meet all emission requirements (e.g., Low NOx, Best Available Control Technology). |

| Efficiency | Base efficiencies can exceed 90% (LHV Basis) depending on process inlet temperature, and with an optional economizer can exceed 93% (LHV basis). |

| Advanced Control Systems | Complete control systems are engineered to optimize system safety and performance. Sigma thermal can supply simple and cost effective standard panels, as well as full process automation and PLC based combustion control / BMS. |

Radiant–Convective Heater

A radiant–convective style heater is the most well-known and commonly used style of direct fired heater. These heaters utilize a bare tube radiant zone in combination with a bare / finned convection section. Vertical cylindrical, A-frame, and cabin style are the most common configurations. Sigma Thermal offers all types of radiant–convective heater designs including API 560 compliant systems.

A radiant–convective style heater is the most well-known and commonly used style of direct fired heater. These heaters utilize a bare tube radiant zone in combination with a bare / finned convection section. Vertical cylindrical, A-frame, and cabin style are the most common configurations. Sigma Thermal offers all types of radiant–convective heater designs including API 560 compliant systems.

Design Features

| Direct Fired Design Flexibility | Careful radiant zone design and row by row convection coil design allow for optimal furnace configuration. Sigma Thermal has extensive experience in process coil design for multi-phase fluids, viscous hydrocarbons, suspended solids, and various gaseous mixtures. |

| Fuel Source and Burner Flexibility | Standard or engineered burner configurations are available for use with both traditional and alternative fuel sources. Both natural draft and forced draft units available. Low emissions burners can be supplied to meet all emission requirements (e.g., Low NOx, Best Available Control Technology). |

| Efficiency | Base efficiencies can exceed 90% (LHV Basis) depending on process inlet temperature, and with an optional economizer can exceed 93% (LHV basis). |

| Advanced Control Systems | Complete control systems are engineered to optimize system safety and performance. Sigma thermal can supply simple and cost effective standard panels, as well as full process automation and PLC based combustion control / BMS. |

Direct Fired Heaters FAQs

The two most common industrial heating systems are direct and indirect fired heaters. Direct fired heaters are preferred in chemical plants and refineries because of their efficiency, while indirect fired heaters are best for confined spaces or tightly sealed operating environments. To help narrow down the best type of direct or indirect fired heater for your application, we answered these FAQs addressing the most common concerns.

How Does a Direct Fired Heater Work?

This type of heating system derives its name from the fact that fuel such as gas, oil, or propane is sent directly into a burner and is combusted with the addition of oxygen. This combustion creates flue gases that transfer their heat to a process fluid circulated throughout the heater’s radiant and convective heat exchange section. As it circulates, the process fluid absorbs heat from the flue gas.

What Is the Difference Between Direct and Indirect Fired Heaters?

The biggest difference between direct fired heaters vs. indirect fired heaters is that an indirect fired heater burns fuel outside of the heated area and then transfers the heat to the desired area using a coil. This allows combustion byproducts to remain within the coil and then be exhausted through the flue. Indirect fired heaters are safer because the process fluid or air being heated is kept separate from the combustion byproducts. Since no exhaust is released back into the space in which they operate, indirect fired heaters are the preferred option in tightly sealed environments.

Direct fired heaters operate with over 92% thermal efficiency. Direct fired heaters can also be adapted to meet the needs of your specific environment, whereas indirect fired heaters come in specific sizes set by the manufacturer and usually cannot be adjusted. This often makes direct fired heaters the preferred option in industrial settings, as they are adaptable, run more efficiently, and are more cost-effective overall. However, unless they are going to operate outdoors, direct fired heating systems need proper ventilation to ensure workplace safety.

What Is the Efficiency of a Direct Fired Heater?

One of the reasons direct fired heaters are preferred in many industrial settings is their efficiency. Since nearly 100% of the fuel in a direct fired heater is converted into heat, fuel consumption and operating costs are lower compared to those of indirect fired heaters. This design effectively warms the target area while minimizing energy loss, leading to a thermal efficiency of 92% (the 8% heat loss is due to water formation during combustion).

Additionally, because they do not use an intermediate medium (such as the heat exchanger found in indirect fired heaters), direct fired heaters provide more rapid heating as combustion instantly generates heat.

How Does Waste Heat Recovery on a Fired Heater Work?

In fired heating systems, waste heat recovery usually works by using a preheater where hot exhaust gases from the heater transfer their heat to the combustion air, preheating it before it enters the burner. By reusing heat energy that would have been wasted, the waste heat recovery system boosts efficiency and reduces the amount of input fuel needed.