Electric Process Heaters

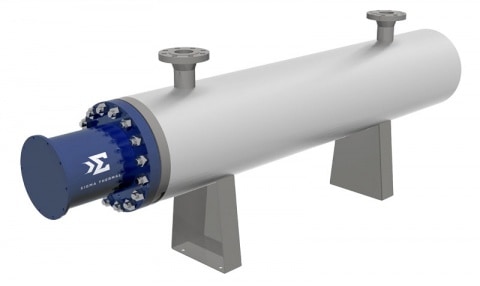

Electric process heaters serve to raise and maintain the temperature of process fluids in industrial equipment and operations. Through an immersed heating element in direct contact with the process fluid, they effectively convert electrical energy to thermal energy to heat the liquid or gas in a system.

As a trusted source for reliable, efficient, and versatile industrial process heating systems, Sigma Thermal designs and manufactures our direct and indirect heating solutions to accommodate myriad applications. At a typical 2 to 60 watts per square inch, our various heater types come standard or as custom-engineered systems built to your exact specifications and site requirements.

Types of Electric Process Heaters

Sigma Thermal’s industrial heating experts are fully versed in various electric process heaters, including basic immersion heaters, skid-mounted circulation heaters, and full heat transfer systems. We design and construct high-quality process heaters according to our customer’s specific needs for even the most challenging industrial liquid- and gas-heating applications. We’ll help fine-tune your process heater or heating system based on your unique temperature rise specifications, process flow conditions, and requirements for thermal efficiency.

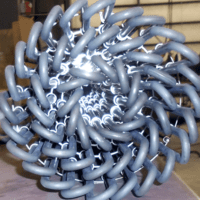

Immersion Heaters

As immersion heaters submerge directly into the fluid within a pipe, vessel, or tank in order to heat it, these versatile heaters are an ideal choice for water, oil, chemicals, and other process liquids or gases. This method of direct heat transfer offers nearly 100% efficiency, as the process fluids absorb almost all of the thermal energy.

With our immersion heaters, you can choose from:

- High-quality 300 Series Stainless Steel, Carbon Steel, and Alloy 800 materials

- Various watt densities

- Different process controls

- SCR, contractor (on/off), or SCR/contractor combination formats

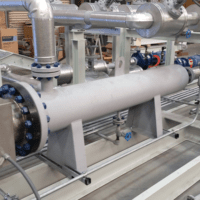

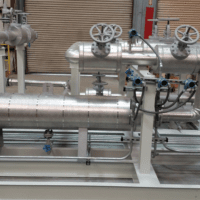

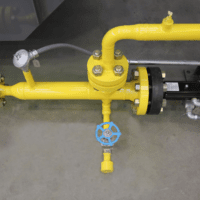

Circulation Heaters

Circulation heaters achieve a more uniform heat in a system by circulating process fluids directly over the heating element, which is located within a vessel. They’re effective for warming process liquids and gases that are typically difficult to heat or must reach high temperatures.

At Sigma Thermal, you can customize your circulation process heater with the following:

- Your choice of 300 Series Stainless Steel, Carbon Steel, Low-Temp Carbon Steel, and Nickel-based metals

- Optional pump

- Various nozzles

- Mounting options

- Flange ratings, 150# to 2500#

- Corrosion protection coating

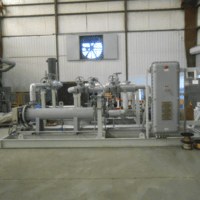

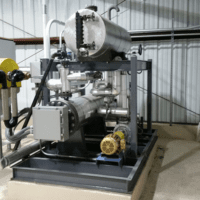

SHOTS Electric Process Heaters

The Sigma Hot Oil Transfer System (SHOTS) electric thermal fluid heater is our pre-engineered solution for generating heat with electricity rather than relying on fuel oil, biomass fuel, or natural gas. SHOTS heaters couple a low-wattage density immersion bundle with an electric circulation heater, resulting in a simple and dependable yet robust thermal fluid heating system.

Sigma Thermal’s innovative SHOTS heaters are available with a host of custom options and design features, such as:

- Medium voltage

- Liquid phase service up to 600 °F

- Advanced, integrated control systems (including modulating controls and industry-compliant safety interlocks)

- Skid-mounting with the primary circulation pump and control panel

- Optional mounted, pre-piped expansion tank

- Compliance for classified areas Class 1, Divisions 1 or 2; ATEX; and more

Applications of Electric Process Heaters

Diverse industries rely on the various types of electric industrial heaters to facilitate a wide range of applications. Some of the most common process heating needs include:

- Creating Asphalt: Using electric process heaters is a common means of ensuring the ideal temperature and viscosity of a mixture when making asphalt.

- Extruding and Molding Components: The extruding and molding fabrication processes depend on process heaters for the consistent temperature control of molten materials when shaping and molding plastics.

- Regulating Liquid Temperatures: By regulating temperatures in vessels like industrial tanks, circulation heaters make it possible to reliably maintain ideal thermal conditions for storing liquids.

- Transporting Oil and Gas: Circulation or immersion heaters are two common choices for heating oil and gas storage tanks, assuring the appropriate viscosity to circulate the oil efficiently.

Request a Quote on Electric Process Heaters

By partnering with experts in the field of custom process heater design, you can better achieve consistent, efficient, and reliable heating for a wide range of liquid- and gas process applications. At Sigma Thermal, we pride ourselves on our innovative process heating systems and tailored solutions, which we package as a skid or ship loose per your needs. Our expert team engineers and produces our electric industrial heaters to comply with such standards as CRN, PED, and ASME Section VIII, Division I, ensuring quality craftsmanship and optimal performance.

From system design to aftermarket support, the Sigma Thermal team is here to help. Contact us to speak directly with an application engineer about your electric process heater needs, or request a quote today to get started.